This process is called PowerVia, and if Intel can integrate it into mass production, it will be able to take a huge leap in the race to create ever smaller nanometer processors.

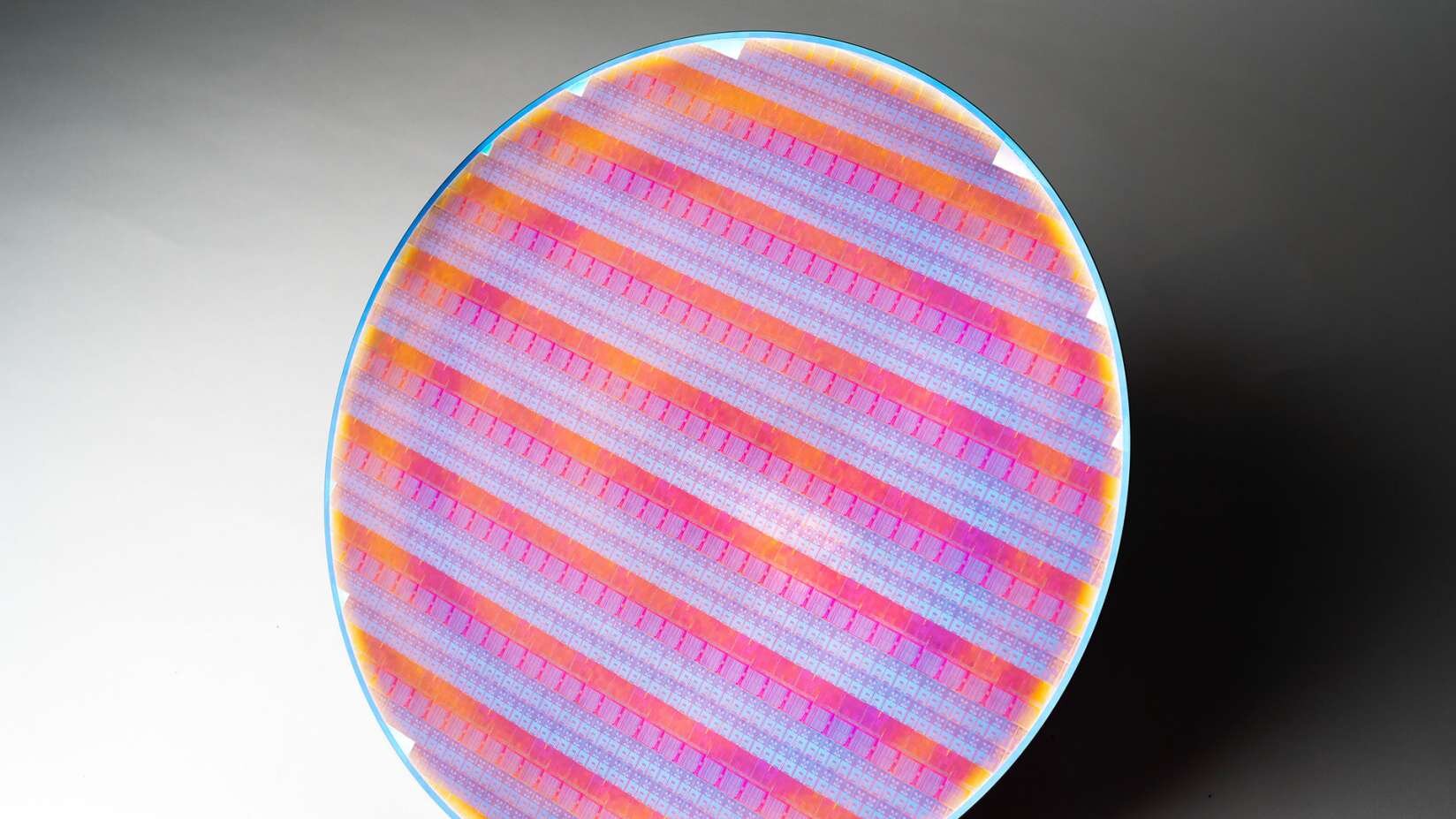

As the company explained in its announcement, PowerVia is a new approach to power delivery, and to achieve it Intel had to revise and radically revise various elements in the way it is manufactured and tested (the first tests are done during manufacturing). Throughout the modern history of computers, processors – and chips in general – have been built like … pizza – that is, from the bottom up, in layers. In the case of processors, the build starts with the smallest features, namely transistorwith continued manufacturing by placing tiny layers of wire connecting transistors and the different parts of the processor (interconnectors).

These layers or layers include the wires that actually carry the current that the processor requires to operate. Once this process is completed, work begins at the bottom of the processor. After flipping, it is placed in the packaging that provides all connections to the outside world (such as terminals) and is ready to be placed in the computer. Unfortunately, today this approach has many problems. As everything gets smaller and denser, the layers where connections and power cables are shared end up becoming a messy web that negatively affects the performance and power efficiency of processors. “Once upon a time, we thought about it, but now it has a massive impact,” says Ben Sell, vice president of technology development at Intel Corporation. In short, the strength and transmission of signals is weakened, which requires some workarounds or more power savings.

The solution that Intel and other major chipmakers are working towards is called “back-end power.” The goal is to find a way to move the power supply wires under the transistors to the “back” of the processor, leaving only the “interface” with the connections. It sounds pretty obvious but why isn’t it done even today? It was just that the ancient method of construction was simpler, and for the most part no problems were noticed – until recently. Of all the chip makers, Intel seems to have finally found the solution. The company has named its new PowerVia power supply technology with Intel aiming to present two research papers at the VLSI 2023 Symposium on Innovation, showing that it works, that it has been tested and that there are positive performance results. For the first time in history, Intel is leaving the pizza industry and chip manufacturing has become two-sided.

More specifically, transistors are built first, as in the past, with the interconnecting layers added later. The silicon disc is then inverted for “grinding” until the bottom plane is exposed to which the small power supply wires are attached. It might be called “silicon technology,” notes Ben Seal, who led PowerVia’s development with his team, but “the amount of silicon left after grinding is negligible.” The cost, performance and strength advantages outweigh the complexity of the process, says Ben Seal, who talks about the multiple advantages. Indeed, the “duplexing” process proved more cost-effective for Intel.

For the average computer user, PowerVia means faster speed and greater energy efficiency while Moore’s Law seems to be working again. According to Intel, the first sample built using the PowerVia approach, the E-core showed a 5% improvement in frequency and >90% cell density with Intel Level 4 debugging detection times. Ben Sale confirmed that we had a significant increase in uptime frequency by a simple “inside movement” of the cables. “What’s cool,” says Intel’s Ben Sell, “is that despite quick changes — like wiring a transistor in the middle of the chip and then introducing a milling technique — we can make transistors look very, very close to what we have using the Intel 4 manufacturing method.” That Intel will start using PowerVia technology in 2024, which is expected to put it at least two years ahead of the competition in the so-called “backward power.” The company hopes that the new technology will help make up for what it has lost to its competitors, both commercial and manufacturing (such as AMD). and TSMC) by offering its customers more powerful and at the same time more energy-efficient processors.

-

8

“Avid problem solver. Extreme social media junkie. Beer buff. Coffee guru. Internet geek. Travel ninja.”

More Stories

'I lost my soulmate': Actor Warwick Davies talks about losing his wife

I chose the same color as the float

15 old Nintendo ads that probably haven't aged well